【Origin Pic】 |

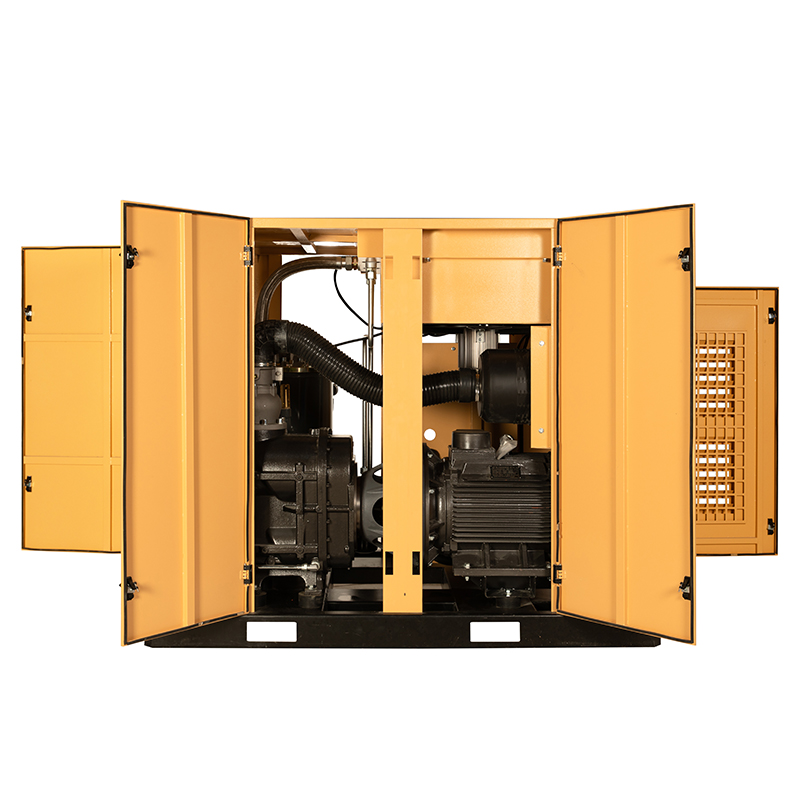

1.The double-stage compressing screw air end reduces the compression ratio of each stage and the internal leakage and improves the volumetric efficiency, it adopt large diameter rotor which is greatly improved the working efficiency compared with the single-stage air end, and the highest exhaust gas volume is achieved. 2.The equipment adopts IE4 permanent magnet synchronous motor, which makes the energy saving efficiency higher than ordinary induction motor and high efficiency induction motor, the soft starting of frequency conversion can reduce the peak current of start-up, realize the smooth start-up, and make it possible to reduce the cost of power equipment. 3.Through the optimal flow control and constant pressure control to reduce the energy consumption, make sure the pressure fluctuation amplitude is controlled within ± 0.01Mpa and the necessary exhaust volume is accurately provided by the best power. 4.The whole machine adopts direct drive, high reliability, low noise and easy maintenance. 5.Full intelligent control, dynamic display of system working condition, real-time monitoring of important parameters. 6.At the same power, the gas production of two-stage compression is increased by 15% compared with single-stage compression, which can achieve energy-saving effect of up to 15%, and save electricity by 45% - 50% compared with ordinary screw air compressor. |

Mobile station

Mobile station Wechat Official

Wechat Official