【Origin Pic】 |

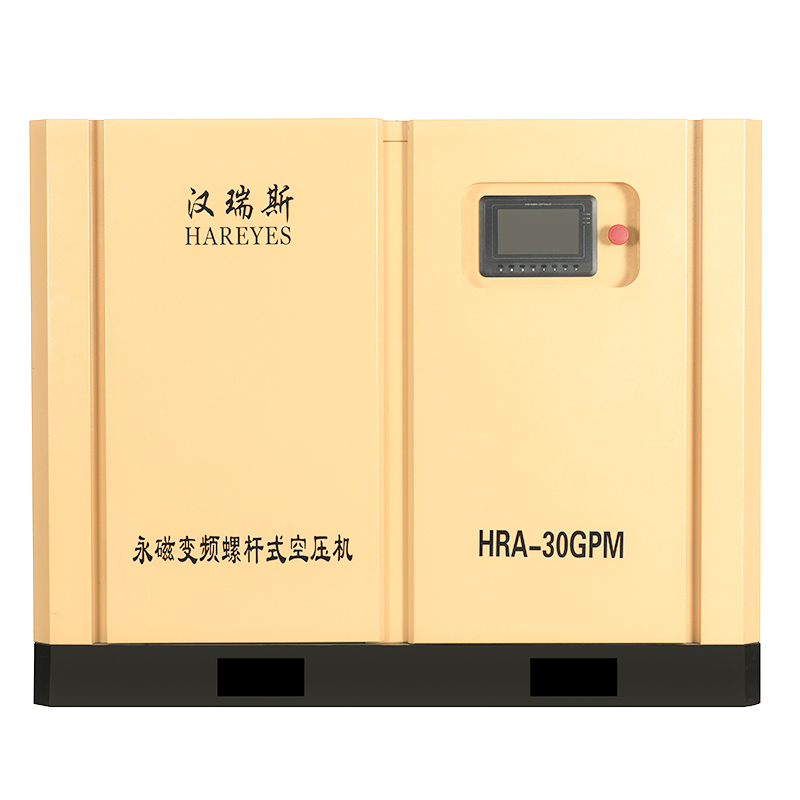

1.Hareyes permanent magnet variable frequency screw air compressor can save the power up to 30%-50% compared with ordinary screw air compressor. 2.The international Hareyes air end with best line design, large air displacement, low noise and high stability. 3.Totally enclosed IE4 permanent magnet synchronous motor is adopted to eliminate material loss and IP54 protection grade, which is safer, more efficient and more energy-saving. 4.The air end and permanent magnet motor adopt the structure of direct connection and separation, which has high reliability, high safety and easy maintenance. 5.The special frequency converter of permanent magnet synchronous motor is adopted to realize stepless speed regulation, constant pressure air supply and soft starting, completely eliminate the loss of reactive power and achieve intelligent gas supply. 6.Full intelligent control, dynamic display of system working condition, real-time monitoring of important parameters, intelligent automatic switch on and off, and continuous operation under unattended condition. |

Mobile station

Mobile station Wechat Official

Wechat Official