about us

Guangdong Hareyes Compressor Manufacturing Co., Ltd.

Address:Building 6, No.27 Zhenma Road, Dalingshan Town, Dongguan City

Phone:+86-400-830-6698

E-mail:mark@rrtmachine.com

Products:Screw air compressor, refrigeration dryer, adsorption dryer, etc.

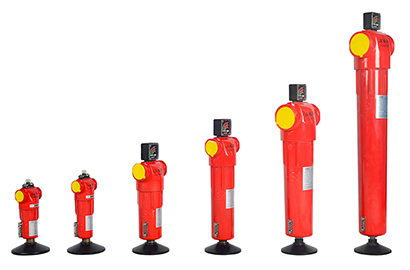

Precision filter is the most commonly used filter in industrial water treatment equipment. It can effectively remove suspended substances in the liquid and can withstand higher filtration pressure. The appearance volume is small, the filter area is relatively large, and the service life is relatively long on average. The precision filters introduced by the company are available in various models and sizes to meet the various needs of customers.

So what are the factors that affect the precision filter during operation? The editor will give you a specific introduction!

1. Feed flow rate

Improving the flow rate of the feed liquid will help prevent concentration polarization and improve the processing capacity of the equipment. However, increasing the pressure increases the energy consumption of the process, leading to increased costs. Generally, the flow velocity in a turbulent flow system is 1-3m/s.

In the spiral module system, it usually operates in the laminar flow area. A turbulence promoting material can be provided on the liquid flow channel, or a vibrating membrane support can be used to generate a pressure wave on the flow channel to improve the flow state and control the concentration difference. To ensure the normal operation of ultrafiltration components.

2, work pressure

The relationship between ultrafiltration membrane permeation flux and working pressure depends on the properties of the membrane and boundary layer. In the actual ultrafiltration process, the latter usually controls the same amount of ultrafiltration permeation. When using the osmotic pressure model, the permeation flux of the membrane is proportional to the pressure, while when using the gelation model, the permeation flux of the membrane is independent of pressure. The permeation flux at this time is called the critical permeation flux. In fact, the ultrafiltration operation should be performed near the critical permeation flux. At this time, the working pressure is about 0.5-0.6MPa. In addition to overcoming the resistance of the permeable membrane, the pressure loss of the fluid passing through the membrane surface must also be overcome.

3, temperature

Working temperature mainly determines the chemical, physical properties and biological stability of the liquid to be processed. It should be operated at the highest temperature allowed by the membrane equipment and processing material, because high temperature will reduce the viscosity of the raw material liquid, thereby increasing the mass transfer efficiency and improving the flux. The relationship between temperature and diffusion coefficient can be seen from the above formula, the higher the temperature T, the smaller the viscosity μ, the greater the diffusion coefficient D. For example, the maximum temperature of enzyme is 25°C, electrocoating is 30°C, protein is 55°C, dairy industry is 50-55°C, and PVA in textile industry desizing wastewater is 85°C.

4. Operation time

As the ultrafiltration process progresses, concentration polarization forms a dense gel layer on the membrane surface, thereby reducing the ultrafiltration flux. The decay of the flux over time is related to the hydraulic characteristics of the membrane module, the properties of the feed liquid and the characteristics of the membrane. After the ultrafiltration runs for a period of time, it needs to be cleaned. This time period is called the operating cycle. Of course, changes in the operating cycle are also related to the cleaning conditions.

5. Feed concentration

With the progress of the ultrafiltration process, the concentration of the feed liquid (mainstream) increases, at this time the viscosity becomes smaller, and the thickness of the boundary layer increases. This is technically and economically unfavorable for ultrafiltration, so the ultrafiltration process should be limited The concentration of the main stream is the maximum allowable concentration.

6. Pretreatment of feed liquid

In order to increase the permeation flux of the membrane and ensure the normal and stable operation of the ultrafiltration membrane, the feed liquid needs to be pretreated before the ultrafiltration. Although the pretreatment process of ultrafiltration is not as strict as the reverse osmosis process, this pretreatment is also the key to ensuring the normal operation of the ultrafiltration process. The commonly used preprocessing method is:

(1) Filter;

(2) Chemical flocculation;

(3) PH adjustment;

(4) Disinfection;

(5) Activated carbon adsorption;

Contact us

Add:No.27 Zhenma Road,

Dalingshan Town, Dongguan City

Tel:+86-769-85608139

Mob:+86-13925235790/ Mr. Liang

E_Mail:hrs@hareyescompressor.com

About us

Company Profile Our team Honor Case PartnerProducts

Air compressor Air dryer Precision filter Gas tank Air compressorNews center

Company news Information Q&A Mobile station

Mobile station Wechat Official

Wechat OfficialCopyright © 2020 Guangdong Hareyes Compressor Manufacturing Co., Ltd. All rights reserved Technical Support【Dongguan website construction】【Admin】【Baidu Statistics】 【Back to homepage】